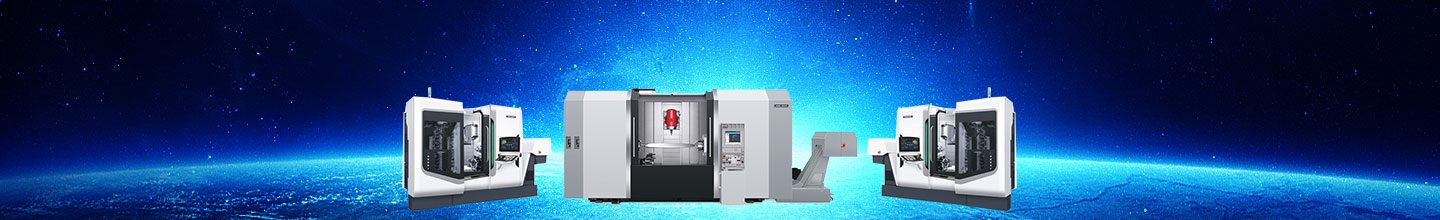

The WDZ 250 type spindle lathe has a central frame, and the WDZ 250 Duo type spindle lathe has two central frames

WDZ type 250 axis lathe with a center frame, WDZ 250 Duo type shaft lathe has two independent center frame, so the processing cost is very low which is characterized in the processing of up and down at the same time, the auxiliary time is very short, many processing methods, such as in a machine tool for drilling, milling and grinding and polishing, automatic processing, simple operation. Because of the long and narrow shape of the machine tools, it is easy to combine the machining units

Performance data for WDZ 250 and WDZ 250 Duo shaft lathes:

Shape, narrow, small footprint, can form a processing unit.

The workpiece height is 1100 mm with a diameter of 250 mm

? the most advanced synchronous drive motor, power 38 kW

Fast forward, up to 40 m/min

Modular machine tool program, according to specific circumstances, adjust the distribution segment

Up to four tool slides

The WDZ 250 type lathe has a central frame, and the WDZ 250 Duo lathe has two independent centers, doubling its productivity

There are many kinds of processing methods: drilling, milling, grinding and polishing on a machine tool

The tool is fast and time-saving in the tower

The automation method is simple

The operation method is optimized and conforms to the ergonomics angle

The WDZ 350 type spindle lathe has a central frame, and the WDZ 350 Duo type spindle lathe has two central frames

Powerful main spindle power up to 64.4 KW, torque up to 1110 Nm; 4 axis machining cost is low; at the same time, loading and unloading, save time - with a single center frame type WDZ 350 axis lathe and is equipped with two independent center frame WDZ 350 Duo type shaft lathe processing efficiency is very high. Short setting time and high processing efficiency.

Performance data for WDZ 350 and WDZ 350 Duo shaft lathes:

Compact structure, small footprint

The workpiece height is 1100 mm with a diameter of 350 mm

? the most advanced synchronous drive motor, power up to 64.4 kW, rated torque of 1110 Nm

Fast forward, up to 30 m/min

Modular machine tool program, according to specific circumstances, adjust the distribution segment

Main axis, turret, center frame and tailstock NC shaft

Low cost 4 axis machining

The WDZ 350 type lathe has a central frame, and the WDZ 350 Duo lathe has two independent centers, doubling its productivity

? integration of semifinished and finished parts memory

The tool is fast and time-saving in the tower

The automation method is simple

The gear hobbing unit is integrated into the machining space

Provide vertical main spindle and optimize chip discharge

The operation mode has been optimized and it meets the requirements of ergonomics

| Chuck diameter | mm | 350 | 250 |

| Drive power (100% start) | kW | 64,4 | 38 |

| X direction total travel | mm | 500 | 320 |

| Y direction total travel | mm | +/-50 | +/-50 |

| Z direction total travel | mm | 1290 | 1290 |

| Tool system * | VDI | 50 | 40 |

next:Ultra precision lathe

English

English Chinese

Chinese